Step-by-step polymer generation

The Polymer Builder is the core of the service since it allows to generate polymers (and polymer melts) through a GUI that guides the user in the polymers construction, offering a step-by-step process that greatly facilitate the complex task of defining the polymers’ composition.

The steps for the polymer generation are 6:

-

Building Block definition

-

Segments definition

-

Polymers Definition

-

System Setup definition

-

Simulation Protocol definition

-

Create the polymeric system

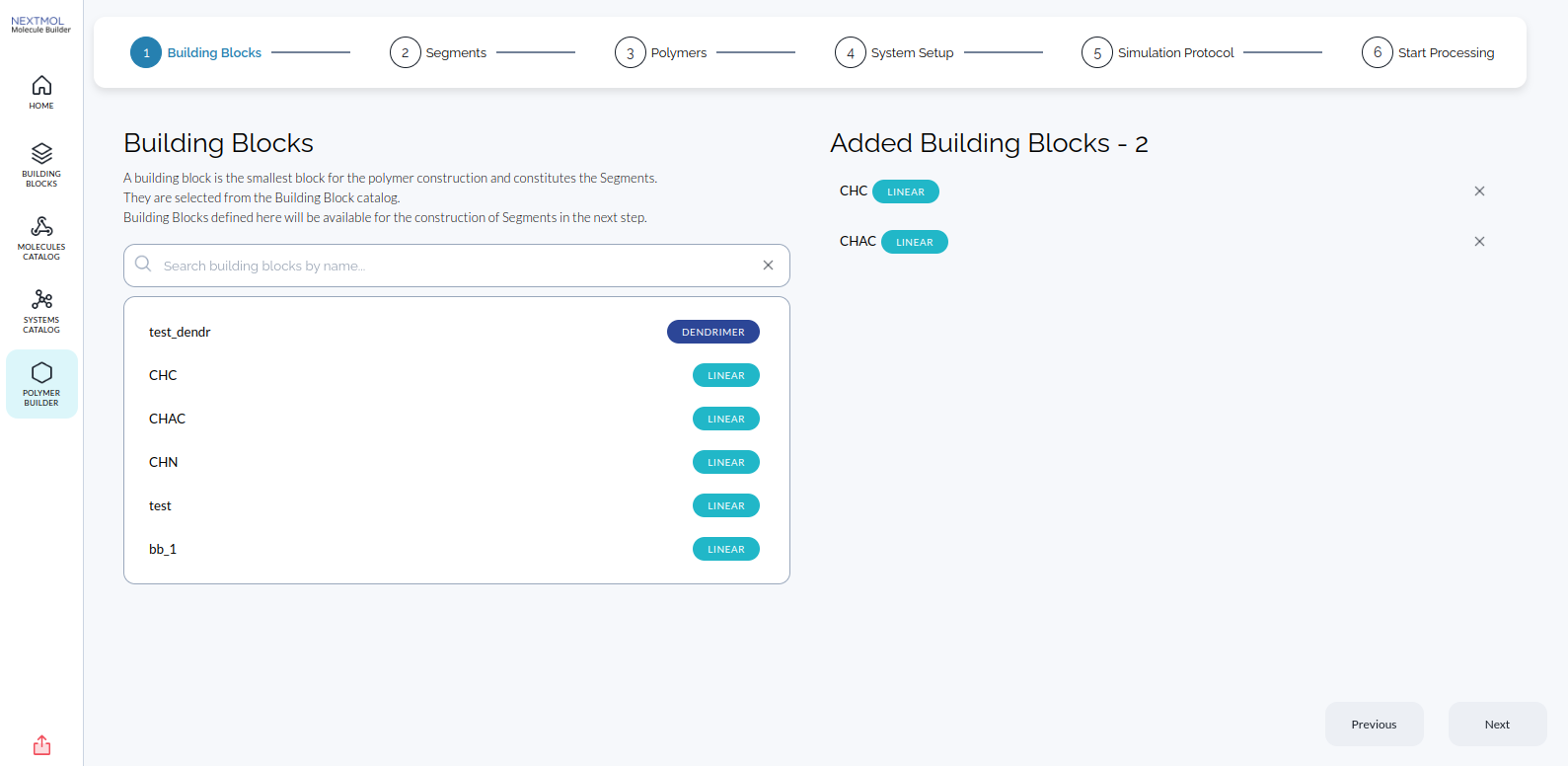

Building Block definition

The first step is simple, since it only requires to select the building block from the catalog that wants to be used in the generation of the polymeric system. To generate new building block, please go to the building block catalog.

Segments definition

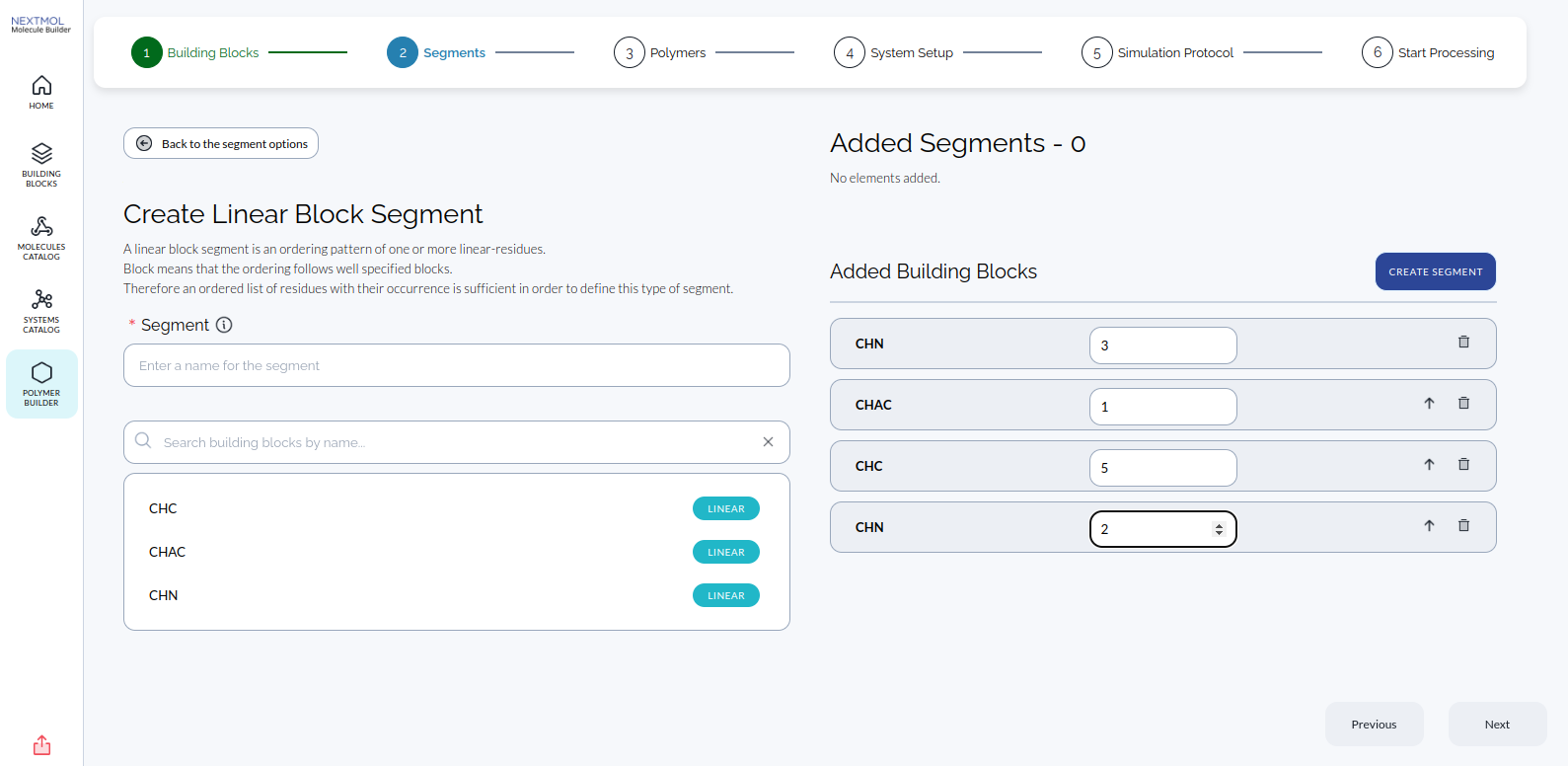

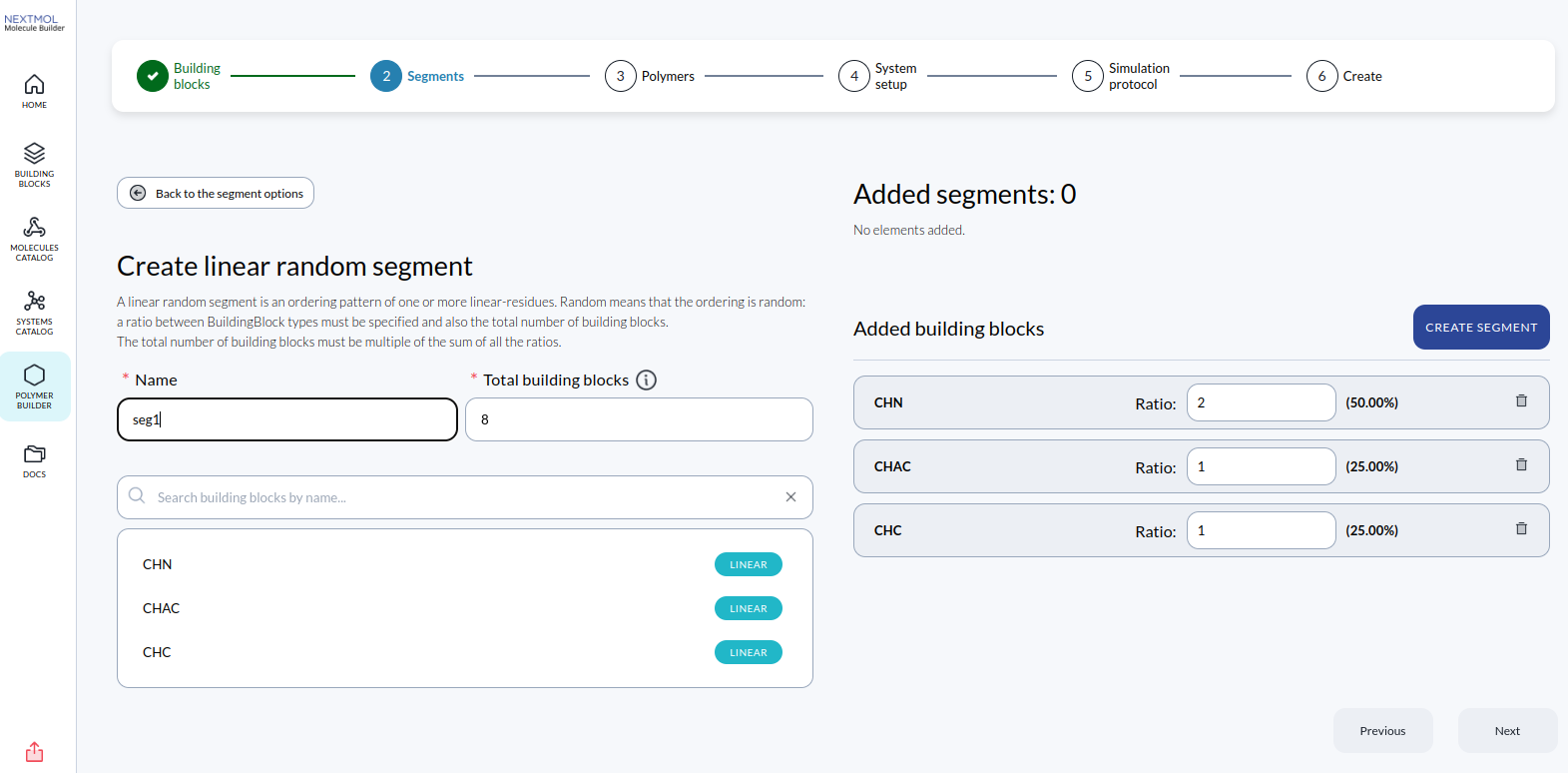

A segment is an ordering pattern constructed using one or more building blocks. It is the second level for the description of the polymer construction. One or several segments can be combined to form a polymer. We have five types of segments: linear block, linear random, dendrimeric from central unit, dendrimeric from repeating unit and peptide. They are described in details in the scientific introduction.

First select the type of segment you want to create and define it according to the following rules.

-

The linear block segment requires a list of building blocks and their occurrence. The order is important and you can repeat several times the same building block. Only linear building blocks are allowed.

-

The linear random segment requires a list of building block and their ratio. The ratio is an integer number and the corresponding percentage is reported automatically on the right side of the selected ratio. The segment is defined by the ratios and the total number of building blocks, that must be multiple of the sum of the ratios. Only linear building blocks are allowed. The building block within the segment will be placed in random order, following the ratios defined by the user. IMPORTANT: the segment level is the only level where randomness can be introduced! Therefore use this option any time that a polymer requires a randomly generated part.

-

The dendrimeric from central unit segment is defined by one single dendrimeric building block and by the generation number of the growth. The building block central unit only is used for generation 0. in all other generations, a new layer of building block repeating units is added. The form also allows to exclude the growth from some connections of the central unit.

-

The dendrimeric from repeating unit segment is the same as the dendrimeric from central unit segment but where the repeating unit of the building block is used as seed for the generation. The

[*:0]of that unit will always be open for connection to a previous building block. -

The peptide segment is defined through a sequence of aminoacids using their one or three-letter codes. Note that in this case the aminoacids are automatically loaded in the platform and the user does not have to define them in the previous step. Also, the peptide structure is obtained through a random walk and not through standard procedures of protein folding. This feature will be available in future realease of NEXTMOL Builder.

When the segment is defined, the CREATE SEGMENT button allows to save the segment and make it available for the next steps.

Polymers Definition

Several type of polymers can be defined. All of them are defined as combination of segments. No randomness can be introduced at this stage. Only at the segments level we can introduce randomness. For every polymer that is defined, a force field must be selected. The force field will define the interaction between atoms of the polymer. The GAFF2 force field is the standard for many applications. The deprecated GAFF force field is maintained due to backwards compatibility issues, but note that its use is not recommended. Other force fields such as GLYCAM-06j, for polysaccharides, or FF19SB, for peptides, are also available.

The user must define a name for every polymer. The assigned name will be used to define the component name in the polymer topology. Currently, only the linear polymer, which allows to define different linear or random segments along with their occurrence, is supported. If you intend to model a dendrimeric polymer, please contact support@nextmol.com

Like for the case of segments, the CREATE POLYMER button allows to save the polymer and make it available for the next step.

System Setup definition

Here, the user selects how many replicas of each defined polymer should be placed in the system. If only one replica of only one polymer is placed in the system, the system is considered a single molecule and the result will be placed in the Molecules Catalog. In all the other cases, the product of the building process is going to be a System. The order of the addition of the polymers in the system (only when more than one polymer is placed in the simulation cell) is selected through the 'Construction order' variable, which may be set to the order of the polymer list or randomly. The polymer(s) must be placed into a suitable cell for the simulation, whose dimensions are also defined in this step. The size of the cell may be defined through two options:

-

Density: the cell is cubic, with the cell sides automatically set to achieve a given density provided by the user, which is 0.1 g·cm-3 by default.

-

Cell sides: the length of each side of the box is provided by the user. In this case, it is the responsibility of the user to define a suitable length for each side of the cell.

For non-expert users, the default value using the density setting is recommended. Additionally, the user can activate the option for hard walls in the Z-dimension, which will assist the user with the generation of a polymer surface. If the hard walls mode is selected, the energy minimization must be activated in the next step.

Simulation Protocol definition

NEXTMOL Builder performs a simulation after the addition of every building block. The simulation can be controlled at this stage, defining if an energy minimization and/or a NVT/NVE simulation should be performed. The default values are usually sufficient in order to guarantee a final simulation system that is energetically stable. Increasing the steps of the dynamics/minimization usually results in a system with lower energy, but also where the polymers are folding on themselves.

Saving of the molecule/system

The last step allows to define a name for the molecule/system that will be generated from the previous steps.

| when the CREATE button is pressed, the new polymer is created in the corresponding catalog. Only from there the user can submit the calculation! See Molecules and Systems catalog |